Cadillac® Vortex CV-P Meter

The meter of choice for high pressure saturated and super-heated steam capable of measuring liquid, steam and gas

The Cadillac® Piezo Electric Vortex (CV-P) Meter is a rate and totalizing meter which is capable of measuring liquid, steam and gas. Due to its piezoelectric sensor technology it is particularly suitable for direct high pressure saturated and superheated steam measurement. In any high pressure saturated or superheated steam application, the Cadillac® Vortex meter is the number one technology choice due to Cadillac®’s accuracy, linearity, reliability and rangeability.

Like many other flow meters, the Cadillac® Vortex meter is a velocity measuring device which computes flow by multiplying the effective cross sectional area of the flow meter with the detected fluid velocity. The meter has no moving parts and consists of a rugged vortex strut with embedded piezoelectric crystals and an amplifier assembly. It detects velocity by measuring the frequency of the vortices, as the peel off the vortex strut of the flow meter. The frequency of these “Karman” vortices is directly proportional to the velocity of the moving fluid, whether this is a gas or liquid.

The Cadillac® Piezo Electric Vortex (CV-P) Meter – Mass flow compensation for super-heated steam.

For compressible fluids, such as superheated steam, an external pressure input (4-20 mADC) into the meter electronics is required to provide mass flow computation. Cadillac® Meter also offers a complete line of Pressure elements.

APPLICATIONS AND FEATURES

Cadillac® Vortex CV-P Meter – Applications

The Cadillac® Vortex CV-P Meter is the meter of choice for high pressure saturated and super-heated steam. This meter can be applied effectively for the following purposes:

- Direct Steam measurements at both boiler and point of use locations.

- Super heat steam applications where extreme pressures/temperatures exist.

- All compressible fluids such and Air, Natural gas, Steam and others.

- No conductive fluids where Magnetic flow meters will not operate.

- Energy measurements where compressible media is being measured.

Cadillac® Vortex CV-P Meter – Features

Cadillac® Vortex CV-P Meter includes the following features:

Accuracy

+/- 0.75% of reading for liquids

+/-1.0% of the reading for liquids, gas, and steam.

No start-up tuning

Automatically selects the optimum settings even in noisy environments

Advanced self-diagnostics

Analysis of the process allows true condition based maintenance and adjustments.

Clear parallel two line LCD display

Displays simultaneous flow rate and total along with process diagnostics

Dual outputs

Simultaneous analog (4-2 mADC) and pulse outputs

Multivariable Option (MASS)

With Mass feature integral temperature sensor (PT1000) mbedded in shedder bar. Electronics provided with saturated steam tables and ideal gas values for other compressible media.

Rangeability

With seasonal steam load variation, the need for a large turndown is essential. Cadillac® Vortex Meters will accurately measure all load requirements with proper sizing. Typical 20 to 1 turndown or better.

Longevity

With no moving parts and through simple robust design the MTBF of the shedder bar is 50 years. With proper system maintenance Cadillac® Vortex Meters will provide reliable, accurate service beyond all flow technologies.

OPERATION PRINCIPLES

Cadillac® Vortex CV-P Meter – Operation Principles

Cadillac® Vortex CV-P Meter includes the following features:

The “Karman” vortex meter principle is clearly illustrated by a flag waving in the wind. As the air passes across the flag pole, vortices peel off and the flag is shaped by these pressure areas. You will notice that, at low wind velocity, the flag will move slowly from side to side. As the wind increases, the flag will start to flutter and ripple, representing the increased frequency and intensity of these flag pole generated vortices as they pass. Wind velocity can thus be determined by measuring the frequency of that flutter.

The shedder bar of the Cadillac® Vortex Meter is a solid piece of metal machined into a shape to maximize the strength of the vortex. As this vortex peels off, it temporarily causes a low-pressure area on one side, which puts sideways stress on the shedder bar. This stress is detected by embedded pressure sensitive piezoelectric crystals, which produce a voltage spike when compressed. By detecting and counting the frequency of these spikes, we can establish fluid velocity. Each vortex meter is tested to determine the relationship between velocity/flow rate and vortex frequency, which results in a meter K-factor expressed in “Pulses/Gallon”. This volumetric relationship is then converted to relative engineering units, which the flow meter converter can then retransmit via a 4-20 mADC current signal or conditioned pulse.

An optional LCD Indicator/Totalizer can display and totalize in engineering units of the users choice. For compressible mediums, such as gases and steam, the meter amplifier can correct for temperature and pressure with the MASS option, which includes a temperature element in shedder bar and look up tables for ideal gases and steam. For mediums other than saturated steam an external pressure source must be provided as shown in the drawing below. Outputs from the meter with the MASS option are compensated and linear for the compressible medium being measured.

DIMENSIONS AND SPECS

Cadillac® Vortex CV-P Meter – Dimensions

Cadillac® Vortex CV-P Meter dimensions are outlined below:

| Flanged Meter Size (inches) | |||||||||||

| 0.5″ | 1.0″ | 1.5″ | 2.0″ | 3.0″ | 4.0″ | 6.0″ | 8.0″ | 10.0″ | 12.0″ | 16.0″ | |

| Dia “A” (Face to Face) |

5.12″ | 5.91″ | 5.91″ | 6.69″ | 7.87″ | 8.66″ | 10.63″ | 12.20″ | 14.57″ | 15.75″ | TBA |

| Dia “B” (Center to Center) |

7.52″ | 7.60″ | 7.87″ | 8.74″ | 9.41″ | 10.00″ | 10.75″ | 12.00″ | 13.43″ | 14.61″ | TBA |

| Dia “C” (Meter ID) |

0.50″ | 1.00″ | 1.50″ | 2.00″ | 3.00″ | 4.00″ | 6.00″ | 8.00″ | 10.00″ | 12.00″ | 16.00″ |

| Weight ANSI Class 150lb | 10lbs | 15lbs | 19lbs | 27lbs | 45lbs | 61lbs | 81lbs | 125lbs | 200lbs | 310lbs | TBA |

| Weight ANSI Class 300lb | 10lbs | 17lbs | 21lbs | 30lbs | 53lbs | 80lbs | 121lbs | 180lbs | 275lbs | 395lbs | TBA |

Cadillac® Vortex CV-P Meter – General Specifications & Sizing

Cadillac® Vortex CV-P Meter includes the following specifications:

- Meter will consist of a full-bore body, vortex shedding bar and remote or integral electronics.

- Meter available with local or remote indication or blind housings.

- Meter available with pulse or analog (4-20 mA) outputs.

- Instantaneous and totalized flow available at local indicator or remotely through outputs.

- Meter measures flow using the Karman vortex shedding principle.

- Vortices induce pulses generated from two piezoelectric crystals hermetically sealed & imbedded in shedder bar.

- Meter electronics shall be capable of direct MASS flow computation for saturated steam without external inputs.

- Meter provides one button auto tuning for setting noise immunity circuits.

- Operating pressure/temperature of meter shall be (Vacuum to 2100 psig)/( -40°F to 500°F)

Cadillac® Vortex CV-P Meter – Sizing Information

The low-end performance of the meter is a function of the fluid’s ability to generate a vortex, which using ultrasonic technology is at the very threshold of when vortices for a given fluid are shed. This threshold is dependent on fluid velocity, density and Reynolds number. The high end of the flow meter is amplitude limited, which ultimately impacts the electronics ability to distinguish one vortex from another. In most cases, this represents 250 ft. /sec for gases and 33 ft. /sec for liquids.

To guarantee satisfactory performance, we will check every vortex meter application for suitability and will require process medium, pressure, temperature and expected minimum and maximum flow rates. For easy reference, we are providing you with a table (see below) for saturated steam at various pressures. The tables list the minimum and maximum flow capability, between which a flow measurement can be made at stated accuracy. Outside those limits, the accuracy will deteriorate somewhat, the extent of which will depend on the quality of the installation.

Saturated Steam Flow Range Table

| Saturated Steam Flow Range Table. (Steam Flow in lbs/hr) | Water/Condensate Range Table. | ||||||||

| Pipe/Meter Size |

5 PSIG | 10 PSIG | 20 PSIG | 50 PSIG | 100 PSIG | 150 PSIG | Meter Size |

Water (GPM) |

Condensate (lbs/hr) |

| Size 0.5″ | 13-85 | 14-105 | 17-140 | 23-255 | 30-435 | 35-615 | 0.5″ | 1.7-27 | 800-12800 |

| Size 1″ | 30-260 | 35-325 | 40-440 | 55-790 | 70-1355 | 80-1915 | 1″ | 3.5-82 | 1730-396400 |

| Size 1.5″ | 60-625 | 65-765 | 80-1050 | 105-1885 | 135-3235 | 165-4565 | 1.5″ | 7-196 | 3540-94600 |

| Size 2 “ | 100-1020 | 110-1265 | 130-1740 | 175-3120 | 230-5360 | 270-7565 | 2″ | 12-325 | 5875-156720 |

| Size 3 “ | 190-1980 | 215-2420 | 250-3355 | 335-6025 | 440-10345 | 520-14600 | 3″ | 24-627 | 11330-302550 |

| Size 4 “ | 335-3450 | 370-4260 | 435-5860 | 580-10500 | 765-18050 | 905-25490 | 4″ | 41-1095 | 19775-528065 |

| Size 6 “ | 730-7550 | 810-9330 | 950-12830 | 1275-23000 | 1670-39540 | 2095-55810 | 6″ | 80-2400 | |

| Size 8 “ | 1565-13500 | 1740-16880 | 2040-22940 | 2730-41160 | 3580-70700 | 4255-99790 | 8″ | 187-4290 | |

| Size 10″ | 2825-21000 | 3140-25800 | 3680-35470 | 4930-63650 | 6460-109300 | 7675-154300 | 10″ | 330-6630 | |

| Size 12″ | 4050-30000 | 4500-3700 | 5270-50800 | 7060-91150 | 9250-156550 | 10990-221000 | 12″ | 475-9500 | |

INSTALLATION

Cadillac® Vortex CV-P Meter – Installation

Cadillac® Vortex CV-P Meter installation instructions are outlined below.

To ensure proper operation, all Cadillac® Steam flow meters should be installed with proper flow conditioning. This requires certain minimum upstream and downstream straight piping runs.

In many steam systems the meter body size will be reduced for optimum meter performance and rangeability. This requires a reducing spool piece as illustrated.

With either reducer or expander piping ensure the upstream pipe length to be ten nominal pipe diameters or more, and downstream straight pipe to be five nominal pipe diameters or more.

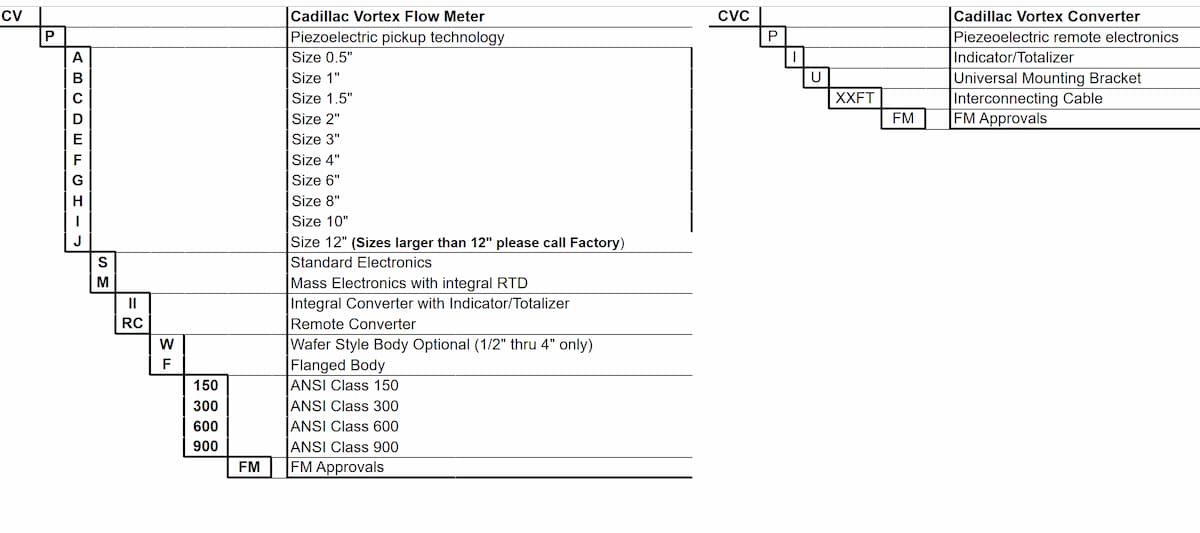

MODEL CODE

Vortex CV-P Meter

Related Articles

Here is Why Energy Sector Industries Benefit from our HEATX-2 BTU Meters

The HEATX2 Btu meter was the first of its kind in the Energy Sector Industry and still provides many capabilities that are unmatched by other energy or Btu measurement devices. As an energy measurement platform, it provides new flexibility, functionality, and...

A Guide to Different Types of Energy Meters [Infographic]

BTU meters are absolutely essential in today’s world; with the electric meter market expected to grow at 6.7% CAGR from 2020 to 2025, there is no stopping this domain from increasing. The industry’s market size is expected to range from $20.7 Billion in 2020 to $28.6...

GET A FREE QUOTE FOR YOUR NEEDS

![A Guide to Different Types of Energy Meters [Infographic]](https://www.cadillacmeter.com/wp-content/uploads/2024/01/different-types-of-energy-meters-400x250.jpg)