Cadillac® HEATX BTU Energy Meter

The choice for accurate energy measurement

The Cadillac® BTU Meter (HEATX) is designed to measure the energy consumed in hot water heating and chilled water cooling systems. The system is a rate and totalizing device, which is capable of calculating and displaying Volume, Energy, Temperatures and Peak Energy usage. Combined with Cadillac®’s superior flow meter technologies the HEATX provides the most accurate, repeatable, and maintenance free energy system available in the industry.

The Cadillac® BTU Meter (HEATX) measures the temperature in the feed and return lines via two precision matched 4-wire RTD’s and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the HEATX will then compute, display, and output the Energy consumed.

The New Industry Standard

Combined with Cadillac®’s superior flow meter technologies the HEATX BTU meter has quickly become acknowledged as the industry standard. Customers choose the Cadillac® HEATX BTU Meter because of proven: accuracy, dependability, consistency, maintenance, reliability and rangeability.

Cadillac® BTU / Energy Meter has the ability to provide the best suited and widest range of application solutions to meet the end users energy measurement needs.

APPLICATION FEATURES

Cadillac® HEATX BTU Meter – Applications

The Cadillac® HEATX BTU / Energy Meter is the meter of choice for energy applications. This BTU meter can be applied effectively for the following purposes:

- Energy consumption data source for energy management system, DCS, district-wide systems.

- Energy-Customer Billing from accurately totalized Energy / BTU meter measurements.

- Basis for internal cost distribution using campus-wide systems.

- Efficiency measuring and monitoring from central control rooms.

- Direct Energy / BTU meter measurements at both Boiler and point of use locations.

Cadillac® HEATX BTU Meter – Features

The Cadillac® HEATX BTU Meter is the meter of choice for energy applications. This meter contains the following features:

- Heating Mode: Where Positive ΔT’s only are totalized.

- Cooling Mode: Where Negative ΔT’s only are totalized.

- Heating/Cooling Mode: Where the flow of energy may be for either heating or cooling. In this mode the energy total is increased regardless of whether the ΔT is positive or negative.

- Charge/Discharge Mode: Where two separate registers totalize positive and negative totals.

OPERATION PRINCIPLES

Cadillac® HEATX BTU Energy Meter – Operation Principles

The Cadillac® HEATX BTU Meter measures the temperature in the feed and return lines via two precision matched 4-wire RTD’s and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the HEATX BTU meter will then compute, display, and output the Energy consumed.

Power is Calculated:

- P = V x p x (htv-htr)

Where:

- P = Power (watts)

- V = Volumetric flow Rate

- p = Density

- htv = Specific enthalpy at Feed temperature

- htr = Specific enthalpy at Return temperature

INSTALLATION

Cadillac® HEATX BTU / Energy Meter – Installation

The Cadillac® BTU / Energy Meter installation is illustrated in the diagram below.

By implementing the CMAG flow meter as part of the HEATX BTU meter System, users remove the most inaccurate component of the system and in turn now have the highest accuracy volumetric flow device available for measuring energy usage. With a 300:1 turn down and +/-0.25% of the rate accuracy the CMAG flow meter effectively doubles the overall accuracy of the entire system by itself, while providing a maintenance free non-mechanical flow technology. Combined with precision matched 4-wire RTD assemblies, and the HEATX BTU / Energy computer Cadillac® Meters offer the most accurate BTU/Energy measurement system currently available for measurement and billing purposes.

The HEATX BTU meter is accurate to OIML R75 Class 4 and EN1434 Standards.

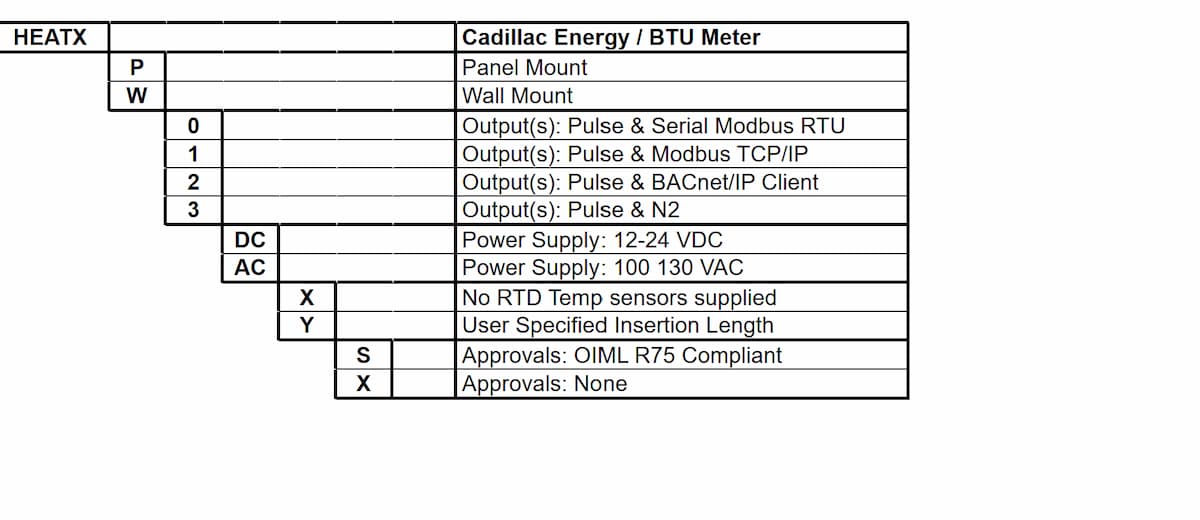

MODEL CODE

HEATX Model Code

Related Articles

Industries That Use Condensate Meters: Where Precision Flow Measurement Matters

In the world of energy, data is power—and nowhere is that more evident than in the industries that rely on condensate meters. From massive power plants to pharmaceutical facilities, industries that use condensate meters all share one thing: the need for accurate,...

How Condensate Meters Work: A Straightforward Guide for Energy Professionals

In the energy industry, accuracy isn’t optional—it’s everything. That’s especially true when it comes to tracking steam usage and reclaiming valuable condensate. Whether you're in power generation, chemical processing, or HVAC systems, understanding how condensate...

GET A FREE QUOTE FOR YOUR NEEDS