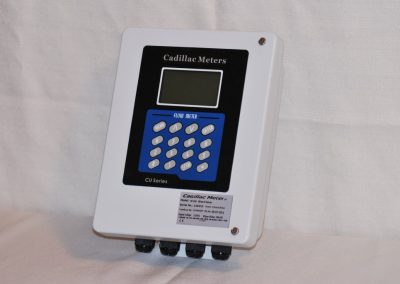

Cadillac® Energy CU-E Meter

The choice for accurate energy measurement

The Cadillac® CU-E BTU Meter is designed to measure the energy consumed in hot water heating and chilled water cooling systems. The meter is a rate and totalizing device, which is capable of calculating and displaying Volume, Energy, and Temperatures.

The Cadillac® CU-E BTU / Energy Meter measures the temperature in the feed and return lines via two RTD transmitters and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the CU-E will then compute, display, and output the Energy consumed.

The New Industry Standard

Combining Cadillac®’s CU-T ultrasonic flow meter with advanced electronics and the capability for temperature inputs the CU-E BTU / Energy meter is quickly become acknowledged as the industry standard. Customers choose the Cadillac® CU-E BTU / Energy Meter because of proven: accuracy, dependability, consistency, maintenance and rangeability.

QUICK CONTACT

DOWNLOADABLE DOCUMENTS

Product Summary

With rising fuel costs the need for improvements in energy measurement has driven the Cadillac® Energy Measurement Systems to be acknowledged as the new industry standard.

APPLICATIONS AND FEATURES

Cadillac® Energy CU-E Meter – Applications

The Cadillac® Energy CU-E Meter is the meter of choice for energy applications. This meter can be applied effectively for the following purposes:

- Energy consumption data source for energy management system, DCS, district-wide systems.

- Basis for internal cost estimation using campus-wide systems.

- Efficiency measuring and monitoring from central control rooms.

- Direct Energy / BTU measurements at both Boiler and point of use locations.

Cadillac® Energy CU-E Meter – Features

The Cadillac® Energy CU-E Meter is the meter of choice for energy applications. This meter contains the following features:

- Heating Mode: Where Positive ΔT’s only are totalized.

- Cooling Mode: Where Negative ΔT’s only are totalized.

OPERATION PRINCIPLES

Cadillac® Energy CU-E Meter — Operation Principles

The Cadillac® CU-E BTU / Energy Meter measures the temperature in the feed and return lines via two RTD sensors/transmitters and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the CU-E will then compute, display, and output the Energy consumed.

Power is Calculated:

- P = V x p x (htv-htr)

Where:

- P = Power (watts)

- V = Volumetric flow Rate

- p = Density

- htv = Specific enthalpy at Feed temperature

- htr = Specific enthalpy at Return temperature

DIMENSIONS AND SPECS

Cadillac® CU-E BTU Meter – Dimensions

The Cadillac® CU-E BTU dimensions are outlined below:

Cadillac® CU-E BTU Meter – General Specifications

The Cadillac® CU-E BTU includes the following specifications:

Energy Meter

- Meter shall consist of remote electroincs, one pair of matched clamp-on transducers, and pair of matched temp trans.

- Meter available with analog (4-20 mA), digital (pulse or relay) outputs, and RS485 Modbus RTU Communications.

- Four line 16 character backlit LCD providing instantaneous Energy, totalized Energy, velocity, and operational status.

- Meter programmed via integral keypad.

- Flow range: 0 to + 40.0 ft/s (0 to + 12.0 m/s), bi-directional flow.

- Accuracy: Typically ± 2.0% of reading at rates < 1.65 ft/s (accuracy also dependent on flow profile).

- Repeatability: 0.2% of Reading.

- Temperature Range: Transducers 4° to +250°F (- 40 to 121°C), Transmitter 4° to +130°F (- 20 to 60°C)

- Meter housing: NEMA 4X (IP65), ABS plastic (standard).

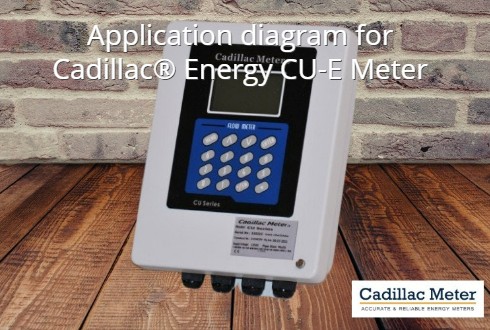

INSTALLATION

Cadillac® Energy CU-E Meter – Installation

The Cadillac® CU-E BTU / Energy Meter installation instructions are outlinde in the diagram below. By implementing the CU-T Ultrasonic flow metering capability and strap-on temperature sensors/transmitters as part of the CU-E Energy System, the user eliminates the need to bring the system down for installation. With a completely non-intrusive system it allows quick and easy retrofit into an online system. With a 100:1 turn down and +/- 2.0% of the rate accuracy the CU-T flow meter provides a cost effective means to provides a flow measurement, while providing a maintenance free non-mechanical flow technology.With no moving parts or flow line obstruction the CU-T has no mechanical drift, which require re-calibration, and does no cause system head loss creating an unwanted heat source (for chilled water systems), as do all other mechanical and differential pressure flow technologies typically used.The CU-E Energy system provides a quick, easy to install, cost effective way to measure energy consumption with reasonable accuracy for the end user.

CU-E Ultrasonic Chilled/Hot Water Energy System

CU-E Water Energy System

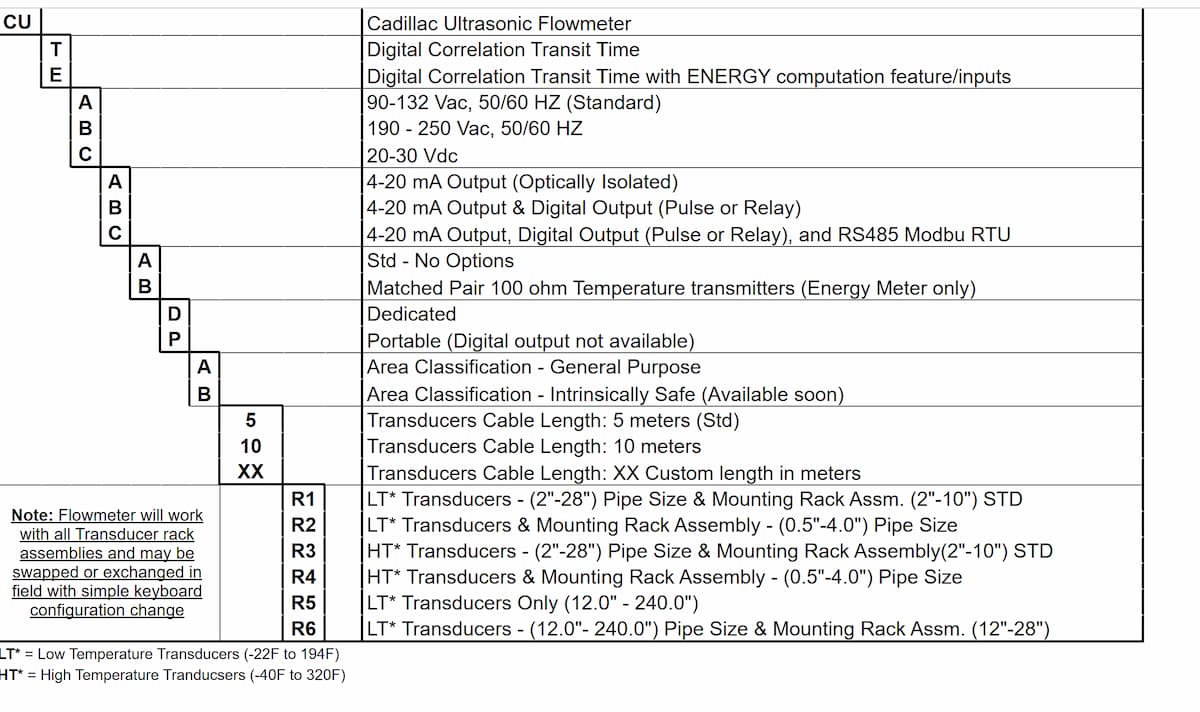

MODEL CODE

Ultrasonic & CU-E Model Mode

Related Articles

Ultrasonic Vs. Magnetic Flow Meters

While selecting the proper flow meter technology for your system is critical, your ability to rely on the meter’s readings will depend more heavily on the application. Every meter technology will have its advantages and disadvantages, but it’s the nuances of your...

Advantages and Disadvantages of Inline vs. Insertion Volumetric Flow Meters

When selecting certain types of volumetric flow meters you may be faced with the option of choosing either an in line flow meter or insertion style meter of the same technology. We will review some of the advantages and disadvantages of each option and how they may...

GET A FREE QUOTE FOR YOUR NEEDS