Cadillac® Energy CMASS Meter

The choice for accurate energy measurement

The Cadillac® CMASS Mass Flow / Energy systems are designed to measure the energy consumed in Super-Heated Steam and Natural Gas applications. The system is a rate and totalizing device, which is capable of calculating and displaying Volume, Volume Flow rate, Corrected Volume, Corrected Flow rate, (Heat & Heat Flow rate in Natural Gas), Mass, Mass Flow rate, (Energy in Steam) , Temperature, Pressure, (Compressibility Factor in Natural Gas), and (Specific Volume & Enthalpy in Steam). Combined with Cadillac®’s superior flow meter technologies the CMASS provides the most accurate, repeatable, and maintenance free Mass Flow / Energy system available in the industry.

The Cadillac® HEATX CMASS Mass flow / Energy meter measures the Volumetric flow via a Cadillac® CV-P, CV-HS, or CV-U Vortex flow meter along with temperature and pressure inputs via separate loop powered transmitters and in turn calculates the Mass flow and Energy of the compressible media (Gas or Superheated Steam) being measured using internal calculations specific to either Steam (IAPWS industrial formulation) or Natural Gas (SGERG AGA-8 Gross equations).

The New Industry Standard

Combined with Cadillac®’s superior flow meter technologies the CMASS Mass Flow / Energy meter has quickly become acknowledged as the industry standard. Customers choose the Cadillac® CMASS Mass Flow / Energy Meter because of proven: Accuracy, dependability, consistency, low maintenance, reliability, and rangeability.

APPLICATIONS AND FEATURES

Cadillac® Energy CMASS Meter – Applications

The Cadillac® Energy CMASS Meter is the meter of choice for energy applications. This meter can be applied effectively for the following purposes:

- Energy consumption data source for energy management system, DCS, district-wide systems.

- Energy-Customer Billing from accurately totalized Energy / Mass Flow measurements.

- Basis for internal cost distribution using campus-wide systems.

- Efficiency measuring and monitoring from central control rooms.

- Direct Energy / Mass Flow measurements at both Boiler and point of use locations.

Cadillac® Energy CMASS Meter – Features

The Cadillac® Energy CMASS Meter is the meter of choice for energy applications. This meter contains the following features:

- Natural Gas Flow: Measures the volume, mass, and gross heat content of natural gas by using analog inputs; volume flow, temperature, and pressure.

- Super-Heated Steam Flow: Measures the volume, mass, and energy content of Super-heated steam by using analog inputs; volume flow, temperature, and pressure.

OPERATION PRINCIPLES

Cadillac® Energy CMASS Meter – Operation Principles

The Cadillac® CMASS BTU / Energy Meter operate differently for gas and heat applications.

CMASS Super Heat Steam

for calculating Mass flow or Energy according to the IAPWS industrial formulation (1997) for the thermodynamic properties of steam. The equations use the pressure and temperature values to determine the specific volume and the specific enthalpy.

Formulas:

- Mass Flow = Volume flow/ Specific volume

- Energy flow = Mass flow x Specific enthalpy measures the temperature in the feed and return lines via two precision matched 4-wire RTD’s and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the HEATX will then compute, display, and output the Energy consumed.

CMASS Natural Gas

For calculating the gas density and compressibility factor based on the SGERG (AGA-8 Gross) equations. The equation uses the pressure and temperature values to determine the Mass flow, Corrected flow, and Heat flow.

Formulas:

Mass Flow = Volume flow x pflow Corrected flow = Mass flow x pref Heat Flow = Mass flow x Hm Where:

pflow = Density at flow conditions pref = Density at reference conditions Hm = Mass gross heating value

Power is Calculated:

- P = V x p x (htv-htr)

Where:

- P = Power (watts)

- V = Volumetric flow Rate

- p = Density

- htv = Specific enthalpy at Feed temperature

- htr = Specific enthalpy at Return temperature

DIMENSIONS AND SPECS

Cadillac® Energy CMASS Meter – General Specifications

The Cadillac® CMASS BTU / Energy Meter specifications are outline below.

- Energy System Specification: The entire Energy Measurement System shall be supplied, calibrated, and commissioned (if necessary) by a single manufacture, Central Station Steam Co, and shall consist of a CMASS Mass Flow / Energy meter, a non-mechanical flow meter, a precision matched temperature sensors/transmitter, and a high accuracy gauge pressure transmitter. A certificate of NIST traceable calibration shall be provided with each system.

- Energy / BTU Meter: Provide a Cadillac® CMASS Mass flow / Energy Meter. The Mass Flow meter shall provide the following measurements at the local display and as outputs* to a Building Control System. Volume, Volume Flow rate, Corrected Volume, Corrected Flow rate, (Heat & Heat Flow rate in Natural Gas), Mass, Mass Flow rate, (Energy in Steam) , Temperature, Pressure, (Compressibility Factor in Natural Gas), and (Specific Volume & Enthalpy in Steam). Output signals shall be either Serial RS-485 (Modbus RTU), and/or via analog (4-20 mADC) and or pulse (Open Collector). Each meter shall be factory configured for its specific application, and shall be reprogrammable using the front panel keypad (no special tools or computer required). *Output options vary by model code and digital communications. Digital communications include Modbus-RTU (Std), BACnet-IP, N2, Modbus-IP optionally.

- Temperature Sensor / Transmitter: Temperature sensor/transmitter shall have an accuracy of +/- 0.1% of temperature span, be 24VDC loop powered, provide a scalable 4-20 mADC output, and field adjustable through a local interface or via digital communications (HART).

- Pressure Sensor / Transmitter: Pressure sensor/transmitter shall have an accuracy of +/- 0.1% of pressure span, be 24VDC loop powered, provide a scalable 4-20 mADC output, and field adjustable through a local interface or via digital communications (HART).

- Flow Meter: Provide a Cadillac® CV Vortex flow meter. The meter will have no moving parts, shall operate per the “Karman” principle. For Superheated steam (CV-P) Piezoelectric crystals mounted external to flow body will by employed to measures torsional effects of vortices on shedder bar. For Natural Gas (CV-U) ultrasonic sensors mounted in sidewall of meter body downstream of shedder bar will be employed to measure vortices. Both meters will have an operational accuracy of +/- 1.0% of rate. A fully developed flow profile must be maintained through piping straight run up and downstream of meter. Meter will have minimum 25:1 turndown at stated accuracy in a “Best Fit” installation. Meter will be provided with integral or remote electronics including a local backlit LCD for parameter viewing and easy interface / configuration. Meter will be preconfigured for application, but may be field adjusted through local display (no special tool or computer required).

INSTALLATION

Cadillac® Energy CMASS Meter – Installation

The Cadillac® CMASS BTU / Energy Meter installation instructions are outlind in the diagrams below.

MASS Flow Measurement for Superheat Steam

MASS Flow Measurement for Natural Gas

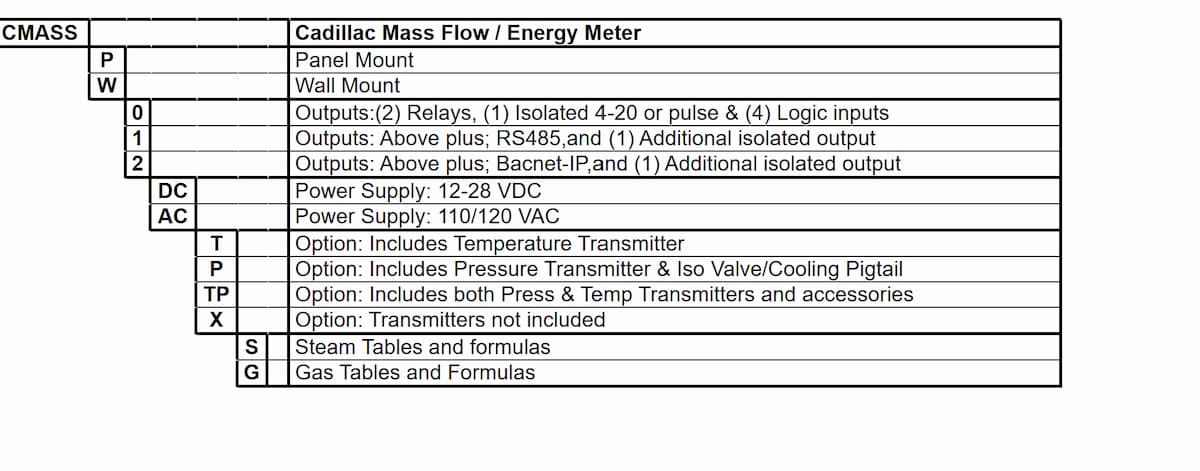

MODEL CODE

CMASS Model Code

Related Articles

Not All Flow Meters Are Created Equal!

As energy usage has become a lightning rod for conversation and studies regarding efficiency, the ability to measure and quantify energy consumption has become forefront in the battle to get a handle on what is being used and how efficient or inefficient that use may...

What Your Mother Never Told You About Measuring Steam Flow

Ok, I’m sure your mother never said word one to you about measuring steam flow, but if she had, I’m sure she would have mentioned that setting up your steam system for precise measurement and minimal losses can be a toughy. The issue boils down (see what I did there?)...

GET A FREE QUOTE FOR YOUR NEEDS