Cadillac® CU-TE Compact Ultrasonic Meter

The Cadillac® Ultrasonic Flow Meters are rate and totalizing meters which are capable of measuring liquids, of all types, non-intrusively.

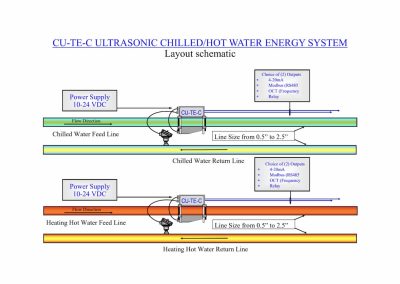

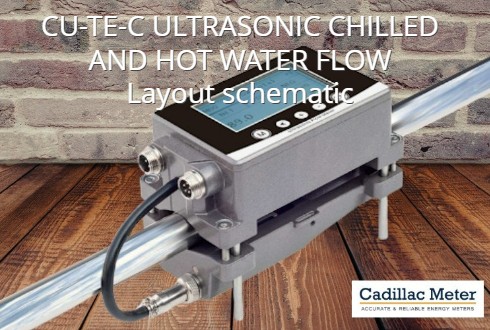

The Cadillac® Ultrasonic Flow Meters are rate and totalizing meters which are capable of measuring liquids, of all types, non-intrusively. Due to the CT-TE Compact design size (0.5” to 2.5”), it is particularly suitable as a low cost solution for Hot and Chilled water measurements.

Integrating Digital Processing (DSP) with advanced correlation detection methods, the flow meter features exceptional performance and flexibility. Combining ease of installation (non-intrusive pipe clamp-on), high accuracy, no moving parts, reliability, low maintenance, rangeability and no pressure drop, the Cadillac® CU-TE Compact Ultrasonic flow meter have become the fastest growing liquid flow technology in the world today.

As an option the Cadillac® CU-TE Compact Meter is an Energy Calculator designed to measure energy consumed in hot water heating and chilled water cooling systems. Supplied with temperature sensors, the calculator integrates the Cadillac® Ultrasonic Flow Meter to provide a low cost flexibility to meet all application needs. Modes of operation include: Heating and Cooling.

With fuel costs still on the rise and a need for improvement in energy measurement in smaller building spaces, Cadillac® is ready to introduce a low cost, compact Energy Measurement System to address these

requirements.

The Cadillac® CU-TE Compact BTU Meter is designed to measure the energy consumed in hot water heating and chilled water cooling systems. The meter is a rate and totalizing device, which can calculate and display Volume, Energy, and Temperatures.

The Cadillac® CU-TE Compact BTU / Energy Meter measures the temperature in the feed and return lines via two RTD transmitters and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the CU-TE Compact will then compute, display, and output the Energy consumed.

The New Industry Standard

Combining Cadillac®’s CU-TE Compact ultrasonic flow meter with advanced electronics and the capability for temperature inputs the CU-TE Compact BTU / Energy meter is quickly become acknowledged as the industry standard. Customers choose the Cadillac® CU-TE Compact BTU / Energy Meter because of

proven: accuracy, dependability, consistency, maintenance and rangeability.

QUICK CONTACT

DOWNLOADABLE DOCUMENTS

Product Summary

Combining ease of installation (non-intrusive pipe clamp-on), high accuracy, no moving parts, reliability, low maintenance, rangeability and no pressure drop, Cadillac® CU-TE Compact Ultrasonic flow meters have become the fastest growing liquid flow technology in the world today.

APPLICATIONS AND FEATURES

The Cadillac® Ultrasonic Flow Meters are rate and totalizing meters which are capable of measuring liquids, of all types, non-intrusively, including:

- Water

- Oil

- Chemical

The CU-TE Compact Ultrasonic Meter is a clamp on type-small pipe size solution that is compatible with piping materials such as:

- Stainless Steel

- Carbon Steel

- Copper

- Resin Pipe PVC

- Other

With its smaller compact size, the CU-TE is suitable for pipeline sizes between 0.5” to 2.5” (Inner Diameter 0.5” – Inner Diameter 2.56”)

Cadillac® CU-TE Compact Ultrasonic Meter – Features

Key product features are as following:

- Simple installation that only takes a few minutes and a user-friendly system that makes for easy operation.

- The new external clamp on design provides the ability to read the flow rate without touching the measurement medium. In return, this can avoid pressure loss or media contamination problems.

- The clamp on feature saves time and costs by eliminating the process of cutting into the pipeline, which also eliminates needing to shut down other equipment for long periods of time to complete the installation.

- 3” 256*128 LCD screen to display a variety of measuring information.

- Supplied with temperature sensors, the calculator integrates the Cadillac® CU-TE to provide flexibility to meet all application needs.

- Has the option to be used as an ultrasonic cooling (heat) meter/btu meter/ energy meter to realize the measurement of energy.

DIMENSIONS AND SPECS

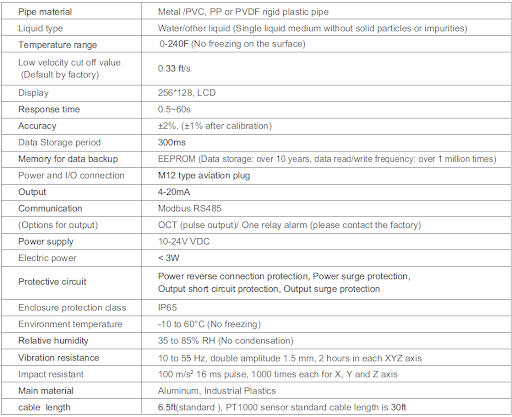

Cadillac® CU-TE Compact Ultrasonic Meter – Specifications

Pipe Material: Metal/PVC, PP or PVDF rigid plastic pipe

Liquid Type: Water/other liquid (Single liquid medium without solid particles or impurities)

Temperature Range: 0-240oF (No Freezing on the surface)

Low Velocity cut off value: 0.33 ft/s

(Default by factory)

Display: 256*128, LCD

Response Time: 0.5-60s

Accuracy: +2%, (+1% after calibration)

Data Storage Period: 300ms

Memory for data backup: EEPROM (Data storage: over 10 years, data read/write frequency: over 1 million times)

Power and I/O connection: M12 type aviation plug

Output: 4-20mA

Communication: Modbus RS485

Options for Output: OCT (pulse output)/ One relay alarm (please contact the factory)

Power Supply: 10-24V VDC

Electric Power: <3W

Protective Circuit: Power reverse connection protection, power surge protection, output short circuit protection, output surge protection

Enclosure protection class: IP65

Environment temperature: -10 to 60oC (No Freezing)

Relative Humidity: 35 to 85% RH (No condensation)

Vibration Resistance: 10-55 Hz, doble amplitude 1.5mm, 2 hours in each XYZ axis.

Impact Resistant: 100 m/s2 16ms pulse, 1000 times each X, Y, and Z axis

Main Material: Aluminum, Industrial Plastics

Cable Length: 6.5ft (standard), PT 1000 sensor standard cable length is 30ft

*Specifications Table

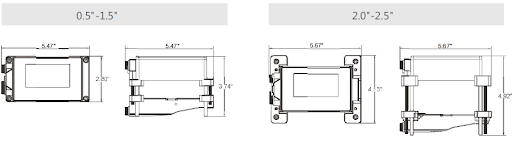

Cadillac® CU-TE Compact Ultrasonic Meter – Sizing (Inches)

FLOW RANGE

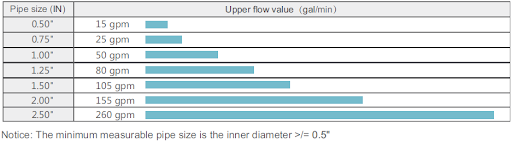

Cadillac® CU-TE Compact Ultrasonic Meter – Flow Range

Pipe Size (In) Upper Flow Value (Gal/min)

0.5” 15 GPM

0,75” 25 GPM

1.00” 50 GPM

1.25” 80 GPM

1.50” 105 GPM

2.00” 155 GPM

2.50” 260 GPM

* The minimum measurable pipe size is the inner diameter >/=0.5”

*Flow Range Table

MODEL CODE

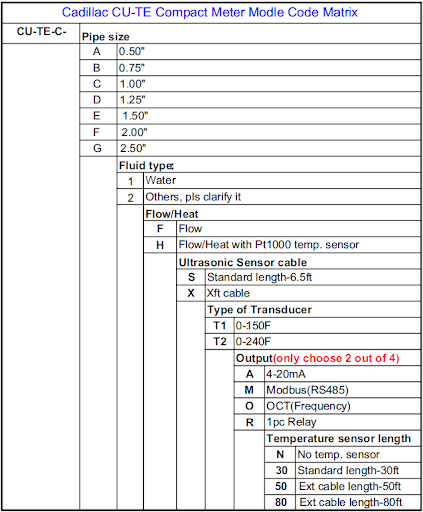

Cadillac® CU-TE Compact Ultrasonic Meter – Model Code

Related Articles

Ultrasonic Vs. Magnetic Flow Meters

While selecting the proper flow meter technology for your system is critical, your ability to rely on the meter’s readings will depend more heavily on the application. Every meter technology will have its advantages and disadvantages, but it’s the nuances of your...

Advantages and Disadvantages of Inline vs. Insertion Volumetric Flow Meters

When selecting certain types of volumetric flow meters you may be faced with the option of choosing either an in line flow meter or insertion style meter of the same technology. We will review some of the advantages and disadvantages of each option and how they may...

GET A FREE QUOTE FOR YOUR NEEDS