Cadillac® CG Condensate Meter

The Meter of Choice – Top Rated by Industry Experts

The Cadillac® CG Gravity Condensate Meter is a totalizing meter which measures liquid or condensate in a full or partially filled gravity flow piping system. In any steam system where condensate is available, the CG Gravity Condensate Meter is the number one choice due to Cadillac’s® accuracy, reliability and infinite rangeability in gravity flow systems.

The underlying principle of the CG Gravity Condensate Meter is: one pound of steam equals one pound of water. Based on this principle, the condensate volume measurement can be converted into a measurement of steam consumption. Cadillac® does this by measuring the volume of condensate while adjusting for the density. This produces a reading in pounds.

Steam is measured either as a commodity to be bought, sold, or to determine the efficiency of a given system. Therefore, the efficiency and reliability of the metering equipment cannot be over-emphasized. No other meter has the capability to measure full rated capacity or a drop at a time, while maintaining an accuracy of +/- 1% of consumption. This is important because steam loads vary widely with seasons and time of day. The CG Gravity Condensate Meter can handle all load and flow variations and are unaffected by any pressure fluctuations in the steam system.

QUICK CONTACT

DOWNLOADABLE DOCUMENTS

Product Summary

The Cadillac® CG Gravity Condensate Meter is a totalizing meter which measures liquid or condensate. In any steam system where condensate is available, the CG Gravity condensate meter is the number one choice due to Cadillac®’s accuracy, reliability and infinite rangeability.

APPLICATIONS AND FEATURES

Cadillac® CG Condensate Meter – Applications

The Cadillac® CG Gravity Condensate Meter is a totalizing meter which measures liquid or condensate. This meter can be applied effectively for the following purposes:

- Data Source for energy management system, DCS, district-wide systems.

- Energy-Customer billing from accurately totalized flow measurements.

- Basis for internal cost distribution using campus-wide systems.

- Process monitoring from central control rooms.

Cadillac® CG Condensate Meter – Features

In any steam system where condensate is available, the CG Gravity condensate meter is the number one choice due to Cadillac®’s accuracy, rangeability, longevity, and modern electronics.

- Accuracy: +/-1% of the reading Capable of measuring full-rated capacity or a drop at a time while maintaining an accuracy of +/- 1% of the flow rate.

- Rangeability: From 0 to full-rated capacity with seasonal steam load variation, the need for a large turndown is essential. Cadillac® Condensate Meters are the only meters that will accurately measure down to virtually no flow.

- Longevity: 100 Years and still going strong Meters in service for over 50 years are common. With proper maintenance Cadillac® Condensate Meters will provide reliable, accurate service for many years.

- Modern Electronics: Meeting the challenges of the next millennium Meters are equipped with electronics capable of registering locally, remotely or interfacing with energy.

OPERATION PRINCIPLES

Cadillac® CG Condensate Meter – Operation Principles

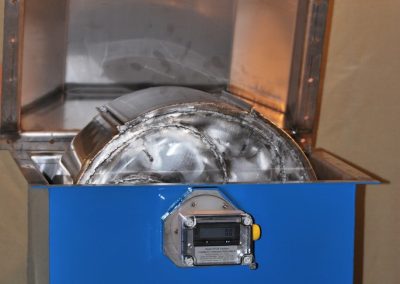

Cadillac® CG Gravity condensate meter operates in the following way. The metering drum consists of 6 scroll shaped compartments. Liquid enters the meter through an axially mounted inlet spout at the center of the drum. As each compartment fills, the excess overflows into the next. This action shifts the center of gravity causing the drum to rotate. The number of filled compartments can be directly converted into steam consumption.

Each of the six precision compartments fills fully and uniformly and tilts the rotor by gravity to advance to the net identical compartment.

DIMENSIONS AND SPECS

Cadillac® CG Condensate Meter – Dimensions

The Cadillac® CG Condensate Meter’s dimensions are outlined below. Please reference the letters with the chart for each meter size.

Cadillac® CG Condensate Meter – Engineering Specifications

The Cadillac® Condensate Meter shall consist of a metal housing, a rotary volumetric measuring drum and a totalizer. The fluid shall be measured by isolating the flow in a scroll-shaped container, six of which shall be provided in the drum.

Materials Of Construction

The meter shall be of materials that are mutually compatible in steam condensate service. The casing shall be constructed of cast iron or stainless steel. The metering drum shall be constructed of machine formed copper or stainless steel. All joints shall be full penetration welds using welding rod of suitable composition for the base metal. Fittings, fasteners and brackets shall be constructed of bronze, brass, stainless steel or high temperature polymers. Bearing bushings shall be constructed of Rulon Gold. External parts such as totalizers may be constructed of high temperature polymers.

Assembly

All metering drum seams shall be readily accessible for visual inspection. Meter parts shall also be easily accessed for maintenance and replacement and shall be arranged to operate without vibration within +/-1% accuracy throughout the entire range from 0-100% full rated capacity. Meter drums may be specified to +/- 0.50% accuracy throughout entire range from 0-100% full capacity.

Totalizer

Meter shall be equipped with a totalizer which shall indicate the quantity of fluid that has passed through the meter since the last reading. Such totalizer shall require no external power source and shall provide a resettable option, an anti-tampering device option and separate contact closure interface for energy monitoring systems. Local or remote mounting options shall be available.

INSTALLATION

Cadillac® CG Condensate Meter – Installation

The Cadillac® CG Condensate Meter has two types of installation – gravity and vacuum.Gravity Installation A gravity installation is intended for use on heating systems where the steam condensate flowing from the meter by gravity is at or near atmospheric pressure.The condensate receiver is optional in an installation where the condensate temperature is moderate and steam traps in the system are reliable enough to prevent excessive steam from reaching the meter. Steam trap selection should include consideration of reliability and uniform flows to the meter. Float and thermostatic traps are generally recommended.It’s important to note that a properly installed F&T trap can actually be located below the meter with moderate steam pressures that will move the condensate up to the meter. This allows the greatest layout flexibility. Refer to trap manufacturer for details.Use of a receiver is recommended in several cases. System design may require that very hot condensate be handled. A receiver is a convenient way to allow for flashing. The receiver also provides surface area for cooling. Flow surges that briefly exceed the capacity of the meter are also accommodated by the receiver.Where several meters are required in parallel because of large flows or several streams, a receiver is an excellent solution. Multiple receiver inlets or outlets reduce header requirements. Receivers are generally sized for a nominal hold time of 5 to 10 minutes depending on surge and flash conditionsVacuum Installation

A gravity installation is intended for use on heating systems where the steam condensate flowing from the meter by gravity is at or near atmospheric pressure.The condensate receiver is optional in an installation where the condensate temperature is moderate and steam traps in the system are reliable enough to prevent excessive steam from reaching the meter. Steam trap selection should include consideration of reliability and uniform flows to the meter. Float and thermostatic traps are generally recommended.It’s important to note that a properly installed F&T trap can actually be located below the meter with moderate steam pressures that will move the condensate up to the meter. This allows the greatest layout flexibility. Refer to trap manufacturer for details.Use of a receiver is recommended in several cases. System design may require that very hot condensate be handled. A receiver is a convenient way to allow for flashing. The receiver also provides surface area for cooling. Flow surges that briefly exceed the capacity of the meter are also accommodated by the receiver.Where several meters are required in parallel because of large flows or several streams, a receiver is an excellent solution. Multiple receiver inlets or outlets reduce header requirements. Receivers are generally sized for a nominal hold time of 5 to 10 minutes depending on surge and flash conditionsVacuum Installation Vacuum-rated condensate meters are used for metering on the suction side of a vacuum pump. A thermostatic air valve is recommended as shown.The vacuum installation is used where condensate is brought back to the power plant through a common return line. In this installation, the master trap isolates the heating system from the vacuum. A reliable, uniform flowing trap such as a float and thermostatic unit is recommended.If the individual traps are reliable enough to prevent steam leakage into the return line, the master trap may be omitted and the meter installed with an air bypass.The air bypass should be used whenever air may enter the system. Care in vertical positioning is required to avoid condensate flowing through the air bypass. Vacuum pump controls should permit continuous operation of the vacuum pump in order to ensure drainage of condensate from the meter.An optional vacuum receiver following the meter also levels out flow conditions.

Vacuum-rated condensate meters are used for metering on the suction side of a vacuum pump. A thermostatic air valve is recommended as shown.The vacuum installation is used where condensate is brought back to the power plant through a common return line. In this installation, the master trap isolates the heating system from the vacuum. A reliable, uniform flowing trap such as a float and thermostatic unit is recommended.If the individual traps are reliable enough to prevent steam leakage into the return line, the master trap may be omitted and the meter installed with an air bypass.The air bypass should be used whenever air may enter the system. Care in vertical positioning is required to avoid condensate flowing through the air bypass. Vacuum pump controls should permit continuous operation of the vacuum pump in order to ensure drainage of condensate from the meter.An optional vacuum receiver following the meter also levels out flow conditions.

PARTS AND KITS

Cadillac® CG Condensate Meter – Drums and Parts

The Cadillac® CG Condensate metering drum is the heart of the Cadillac® Condensate Meter. Cadillac® Meter is recognized for building the drum extra tough, with more metal than the original. We guarantee the same patented design with the same precision.

Cadillac® Meter Drums and Parts include:

- All welded construction which provides strength

- No lead seams

- Virtually permanent calibration

- Exact replacement Cadillac® Condensate Meter spout parts – this helps maintain excellent accuracy

Cadillac® CG Condensate Meter – Maintenance Kits

Cadillac® CG Condensate Meter Maintenance Kits are complete packages of all of the items that you need to rebuild a Cadillac® Condensate Meter. It has already been preassembled as to limit your time on site. Meter maintenance kits are available for both cast iron/brass and stainless steel meters. All parts are 100% interchangeable, except for the casing gaskets.

Our customers tell us that a typical meter rebuild using our complete packaged kit takes about one hour. Our kits include:

- Bearing Assemblies

- All Gaskets

- All Fasteners

- Counter Drive Shaft with Cross Arm

- Drum Bearing Rings (E-G Kits only)

See more details on what parts are included for each kit.

| Maintenance Kit Part Numbers | ||

| Cast Iron/Brass | Stainless Steel | Description |

| KA103 | KA103-S | Size “A” |

| KB104 | KB104-S | Size “B” |

| KC105 | KC105-S | Size “C” |

| KD106 | KD106-S | Size “D” |

| KE107 | KE107-S | Size “E” |

| KF108 | KF108-S | Size “F” |

| KG109 | KG109-S | Size “G” |

| Qty. | Maintenance Kit Parts |

|---|---|

| 2 | Bearing Bracket Roller Assy |

| 3 | Spout Screws |

| 14 | Flange Bolts |

| 1 | Flange Gasket |

| 1 | Spout Gasket |

| 1 | Counter Drive Shaft w/ Cross Arm |

| 1 | Counter Drive Shaft Bushing |

| 6 | Counter Housing Screws |

| 1 | Counter Housing Gasket |

| 2 | Bearing Bracket Roller Assy |

| 3 | Spout Screws |

| * | Flange Bolts *(E-32, F-40, G-48) |

| * | Flange Nut *(E-32, F-40, G-48) |

| 2 | Flange Gasket |

| 1 | Spout Gasket |

| 1 | Counter End Bearing Ring |

| 1 | Spout End Bearing Ring |

Cadillac® CG Condensate Meter – Totalizer Specifications & Parts

The Cadillac® Condensate Meter Maintenance Kits contain the following parts. Where multiple parts are shown, they apply to their respective meter size as indicated by the blue letter in the part number.

Our Cadillac® Condensate Meter Totalizers incorporate the most modern electronics available. All working parts are hermetically isolated from the condensate. Totalizers are available in local, remote, and combination units. The local version shown bolts directly to the meter. No wiring is required. The totalizer parts are also offered for electronic and mechanical units.

Totalizer features include:

- 8 Digit counter fully calibrated for your application

- Contact closure output for energy management system

- 2 Year replaceable internal battery with back-up battery

- High temperature and humidity resistant

- Complete installation kit included

- Magnetic sensor technology

- Easily installed

The stand calibrations for the totalizer are shown below.

| Meter Size | A | B | C | D | E | F | G |

| Capacity For Model | EA140 | EB140 | EC140 | ED140 | EE140 | EF140 | EG140 |

| LB/Switch Closure | 0.4167 | 0.8333 | 1.2500 | 2.5000 | 5.0000 | 10.8333 | 20.0000 |

| Nominal Closures/Min. | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Reading Multiplier, 1= | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

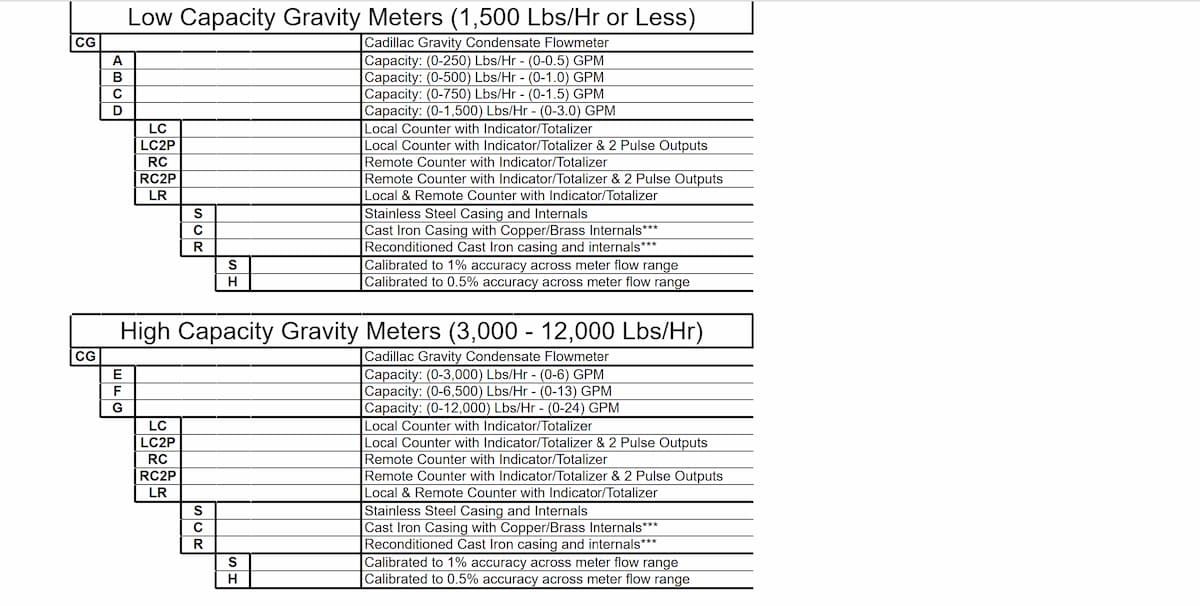

MODEL CODE

CG Mass Gravity Condensate Meter Model Code

Related Articles

Piping Requirements For Flow Meter Installation

A distorted fluid velocity profile is one of the most common reasons for inaccurate flow meter readings. Swirls or other distortions in the flow are caused by the tees, elbows and valves that make piping systems functional. But, to keep your flow meter functional as...

Metering A Heating System: Condensate Vs. Steam Measurement

To calculate energy usage and loads for a heating system, the question is: Which side of the heating system should we measure to provide the most accurate and encompassing measurement results? The simple answer would be the steam side since this is the heating medium...

GET A FREE QUOTE FOR YOUR NEEDS