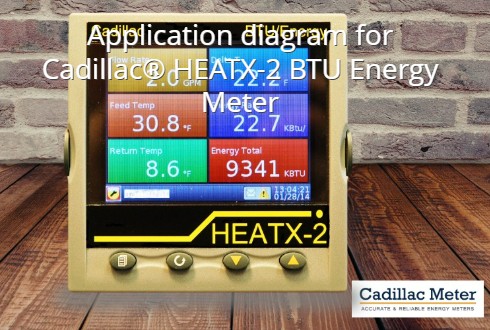

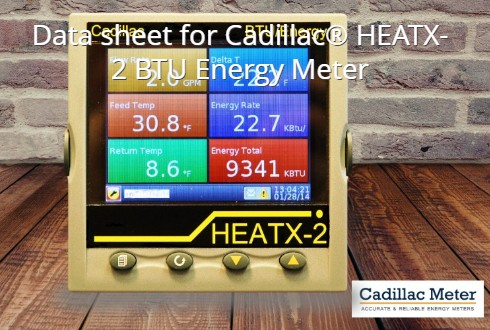

Cadillac® HEATX-2 BTU Energy Meter

The new choice for accurate energy measurement

The NEW Cadillac® HEATX-2 BTU Meter is the first single or dual measurement system, designed to measure the energy consumed in Single or Dual Channel Hot/Chilled water, Condensate (Total Heat BTU), Single pipe Heat/Cool, and Forward/Reverse flow Heating or Cooling systems. The system measures, calculates, displays, and stores energy consumption, which include Volume, Energy, Power, and Temperatures. Key features include a graphical color TFT VGA display, an onboard memory for archiving, a 10/100base T Ethernet port with a wide variety of communication protocols, and a USB connection. Combined with Cadillac ®’s superior flow meter technologies the HEATX provides the most accurate, reliable, and maintenance free energy system available in the industry.

The Cadillac ® HEATX-2 was designed with 50 MB of onboard flash memory for data archiving for redundancy, if connected to a BAS/BMS. Or stand alone for users without a building automation system. Once archived data may be transferred via Ethernet or USB and can be viewed on Energy Review archiving software optional with each HEATX-2 system.

APPLICATIONS AND FEATURES

Cadillac® HEATX-2 Energy / BTU Meter – Applications

The Cadillac® HEATX-2 single or dual BTU / Energy Meter is the meter of choice for energy applications. This BTU meter can be applied effectively for the following purposes:

-

Energy / BTU consumption data source for energy management system, DCS, district-wide systems.

-

Energy / BTU Customer Billing from accurately totalized Energy / BTU meter measurements.

-

Basis for internal Energy / BTU cost distribution using campus-wide systems.

-

Efficiency measuring and monitoring from central control rooms.

-

Direct Energy / BTU meter measurements at both Boiler and point of use locations.

The Cadillac® HEATX-2 BTU Meter is the meter of choice for energy applications. This meter may compute any one or combination of two of the following features:

-

Heating Mode: Where Positive ΔT’s only are totalized.

-

Cooling Mode: Where Negative ΔT’s only are totalized.

-

Heating/Cooling Mode: Where the flow of energy may be for either heating or cooling. In this mode the energy total is increased regardless of whether the ΔT is positive or negative.

-

Charge/Discharge Mode: Where two separate registers totalize positive and negative totals.

-

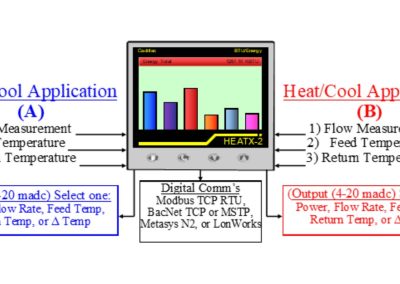

For Single or Dual Hot/Chilled Water

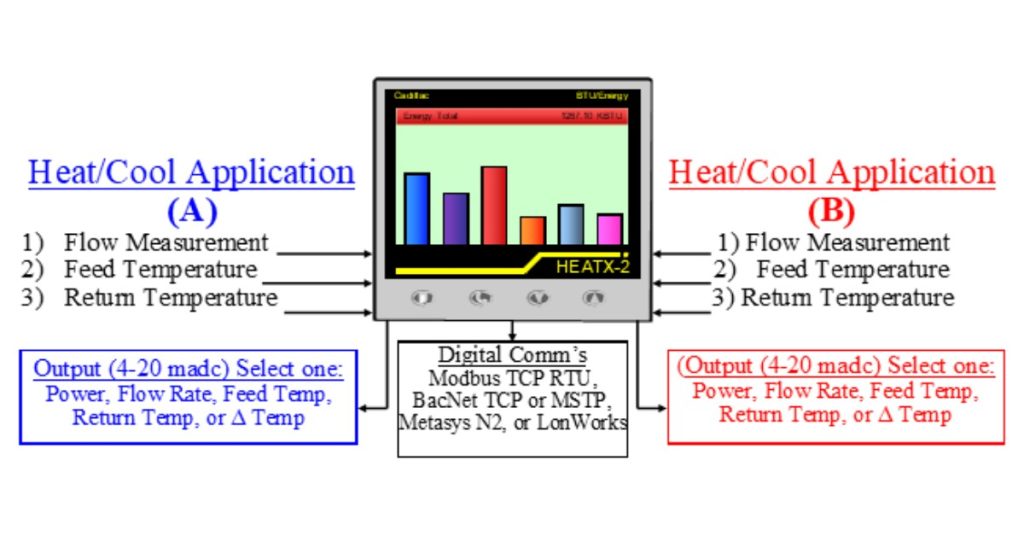

The Cadillac® HEATX-2 measures the temperature in one or two separate feed and return lines via two precision matched RTD transmitters. This then calculates the weight density and enthalpy of the water. In addition, by measuring the volume of water flowing in two separate lines either via the Cadillac® flow meter or other meter technology that provides an analog (4-20 ma) output, the HEATX-2 system will then compute, display, and output the Energy consumed.

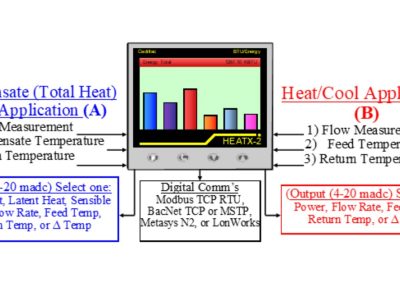

For Condensate (Total Heat BTU)

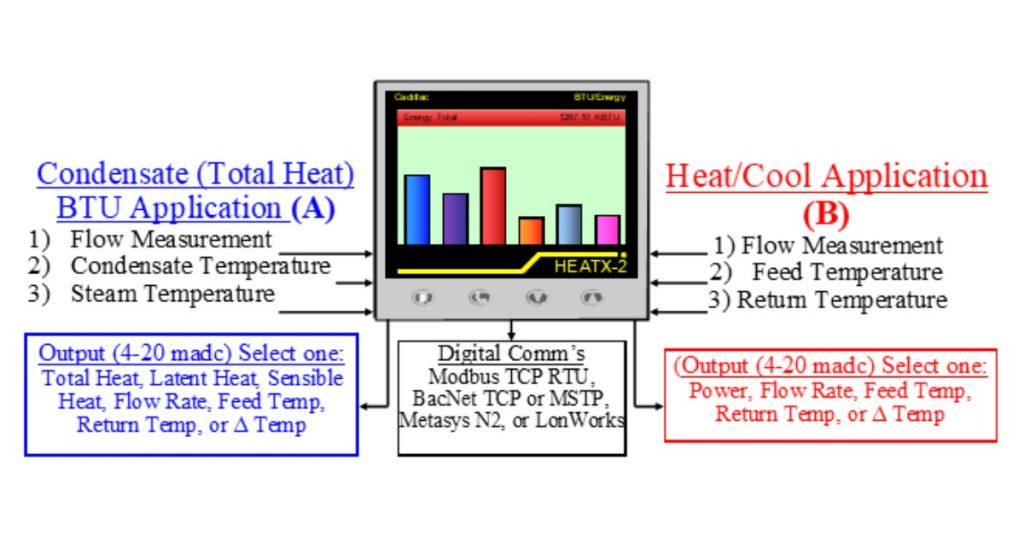

The Cadillac® HEATX-2 measures the temperature from the Condensate line and the Steam line that is brought in by two precision RTD transmitters. This will calculate the weight density and enthalpy of the water and BTU content of Saturated steam. In addition, by also measuring the volume of Condensate flowing (Gravity or pumped), via the Cadillac® flow meter providing an analog (4-20 ma) output, the HEATX-2 system will then compute, display, and output the Energy consumed feeding into the HEATX-2 (Total Heat BTU’s), Energy supplied to Hot Water Loop (Latent HEAT BTU’s) and the remaining energy (Sensible Heat BTU’s) in the condensate. This eliminates the need to measure Steam flow and Heating Hot Water flow with temperatures. Also, by eliminating the Compressible fluid measurement of the Steam, the overall accuracy of the measurements improves. Lastly, the second channel of the HEATX-2 may be used to measure the Chilled Water cooling into the building.

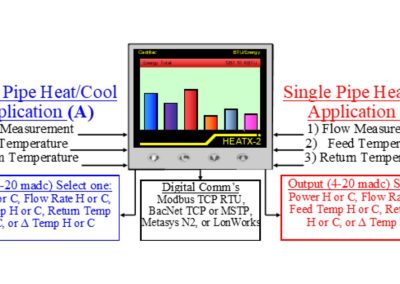

Single pipe Heat/Cooling

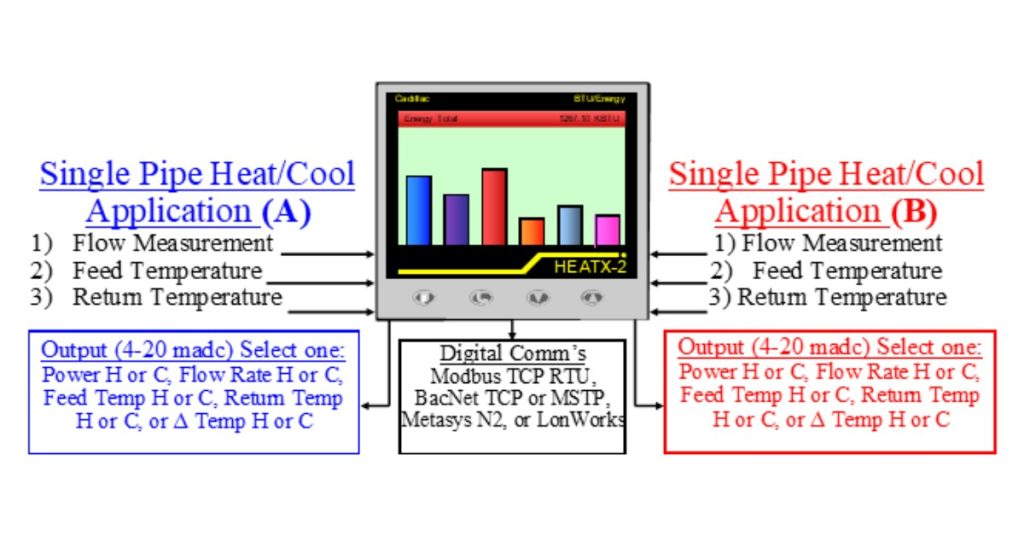

The Cadillac® HEATX-2 measures the temperature in the separate feed and return lines via two precision matched RTD transmitters, and from this it calculates the weight density and enthalpy of the water. When measuring in a single pipe system the HEATX-2 switches modes (Heating to Cooling or Cooling to Heating). The HEATX-2 automatically recognizes the change and starts calculating in dedicated registers to the appropriate heating or cooling values. All registers are accessible via comms for importing static or live data. Additionally, when measuring the volume of water flowing either via the Cadillac® flow meter or other meter technology providing an analog (4-20 ma) output, the HEATX-2 system will compute, display, and output the Energy consumed. If proximity permits, the HEATX-2’s Dual Channel measurement capability could provide the energy measurement for two Single pipe Heating/Cooling buildings simultaneously.

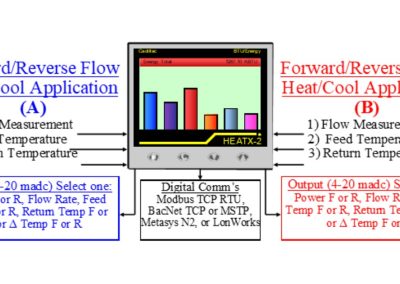

Forward/Reverse flow Heating or Cooling

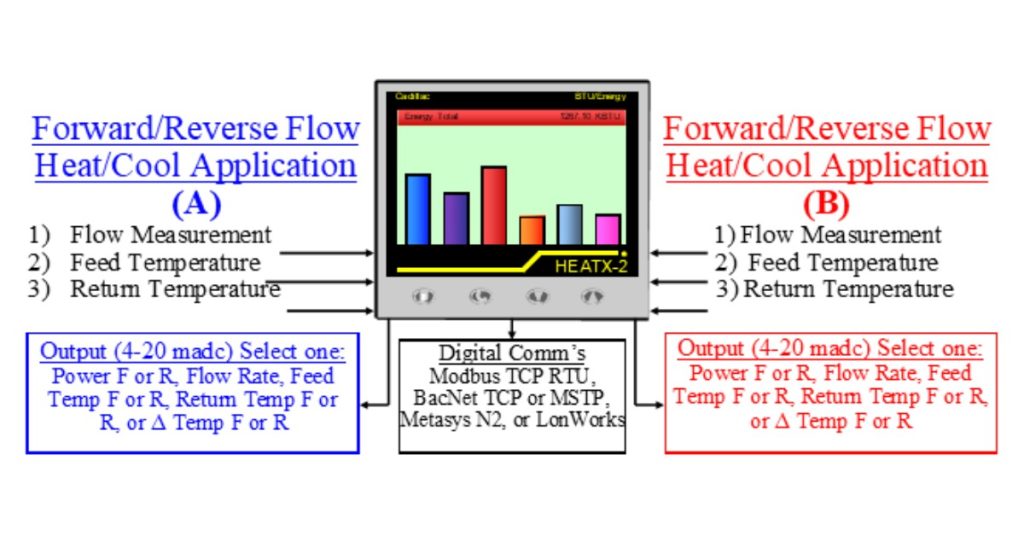

The Cadillac® HEATX-2 measures the temperature in the separate feed and return lines via two precision matched RTD transmitters, which will calculate the weight density and enthalpy of the water. When measuring in a Forward/Reverse flow Heating or Cooling systems the HEATX-2 automatically recognizes the change in flow direction and starts calculating in separate registers for the Cooling or Heating values. The HEATX-2 also has a contact output that may be used to notify when the flow direction changes for either local or remote notification. All registers are accessible via comms for importing static or live data. When measuring the volume of water flowing via the Cadillac® bidirectional flow meter, the HEATX-2 system will then compute, display, and output the Energy consumed.

OPERATION PRINCIPLES

Cadillac® HEATX-2 BTU / Energy Meter – Operation Principles

The Cadillac® HEATX-2 BTU Meter measures the temperature in one or two feed and return lines via precision matched RTD’s and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via one or two Cadillac® flow meters (or any volumetric flow meter with a analog output), the HEATX-2 BTU meter will then compute, display, archive, and output the Energy consumed.

Power is Calculated:

-

P = V x p x (htv-htr)

Where:

-

P = Power (BTU/Hr)

-

V = Volumetric flow Rate (Gal/Hr)

-

p = Density

-

htv = Specific enthalpy at Feed temperature (Btu/Lb)

-

htr = Specific enthalpy at Return temperature (Btu/Lb)

INSTALLATION

Cadillac® HEATX-2 Dual BTU / Energy Meter – Installation

The Cadillac® BTU / Energy Meter installation is illustrated in the diagram below.

By implementing the CMAG flow meter as part of the HEATX-2 BTU meter System, users remove the most inaccurate component of the system and in turn now have the highest accuracy volumetric flow device available for measuring energy usage. With a 300:1 turn down and +/-0.25% of the rate accuracy the CMAG flow meter effectively doubles the overall accuracy of the entire system by itself, while providing a maintenance free non-mechanical flow technology. Combined with precision matched RTD transmitter assemblies, and the HEATX-2 BTU / Energy computer Cadillac® Meters offer the most accurate BTU/Energy measurement system currently available for measurement and billing purposes.

The HEATX-2 BTU meter complies with OIML R75 Class 4 and EN1434 Standards.

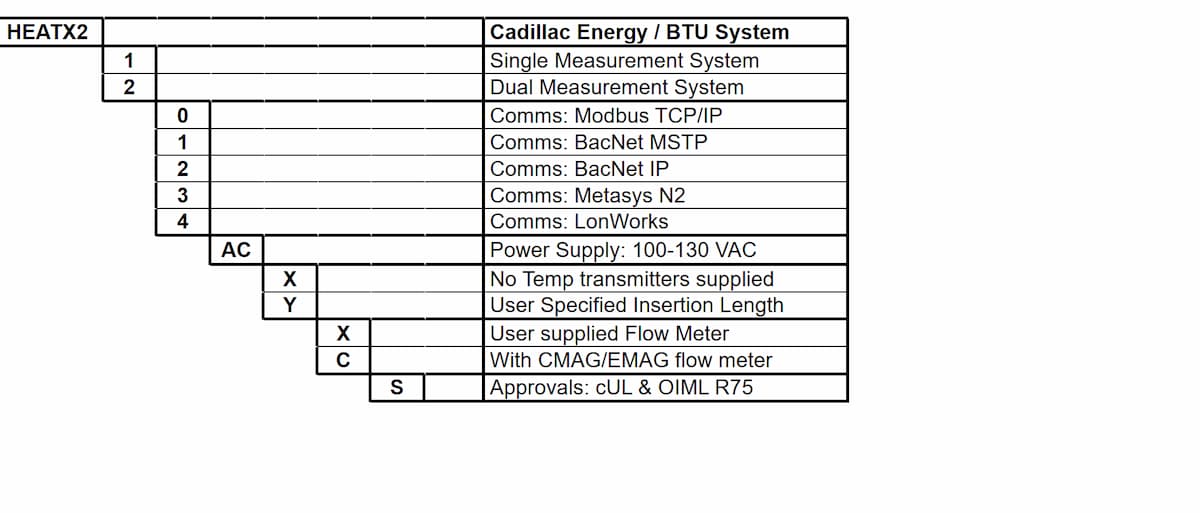

MODEL CODE

HEATX-2 Model Code

Related Articles

Truth in Specsmanship, Part 1

Most of today’s flow technologies (paddle wheel, turbines, orifice plates, variable area, pitot tube, vortex, and magnetic) are volumetric, meaning that these devices measure velocity and then calculate volume by using a known cross section area (Velocity...

Mechanical Flow Meters vs Magnetic Flow Meters

Magnetic flow meters are increasingly taking the place of traditional mechanical flow meter designs. While they both measure the flow of a liquid in a pipe, they do so in different ways. The most common mechanical flow meters are inserted into a pipe and use a...

GET A FREE QUOTE FOR YOUR NEEDS