Cadillac® CMAG Pumped and Gravity

Condensate Meter

The CMAG Pumped and Gravity Condensate Meter is Recognized as the New Industry Standard

Since its introduction, the Cadillac® Magnetic Flow Meter has quickly become acknowledged as the industry standard for both pumped and gravity condensate measurement

The Cadillac® CMAG condensate and gravity magnetic flow meter has been designed specifically for the requirements of retrofit in pumped and gravity applications. With a unique flow tube design that distributes the voltage generated by the induced magnetic field evenly throughout the entire flow tube area, the Cadillac® CMAG is able to accurately measure flows in just about any location it can physically be installed. With unprecedented low flow capabilities and a 300:1 turndown at +/- 0.25% of rate or reading accuracy it provides the most versatile and accurate volumetric flow measurement available. The only installation requirement for the CMAG is that the flow tube is completely flooded when measuring, and that 1.5 pipe diameters of straight run up and downstream of the meter centerline are available. (In gravity applications it may be required to install a piping “Wet Leg” to ensure the flow tube is flooded at all times) If 1.5 diameters from centerline are not available (2” meter size and below the 1.5 diameter straight run requirement is met by the flow tube itself) then the meter becomes a +/- 0.50% accurate device without any piping straight run or flow profiling of any kind. In any condensate system the Cadillac® CMAG magnetic flow meter has quickly become the number one technology choice due to Cadillac®’s accuracy, linearity, reliability and rangeability.

The New Industry Standard

Historically, liquid flows have been measured by mechanical or differential pressure producing flow devices/meters. However, as with any mechanical system, the meters are subject to wear and tear and require regular maintenance and calibration. Worse most of these technologies have very limited turndown capabilities, which mean that either accuracy suffers or the meters no longer measure when flows drop below certain velocity thresholds. The Cadillac® CMAG eliminates all of these problems with no moving parts, a much higher accuracy (+/- 0.25% of rate) and a 300:1 turndown, effectively rendering all mechanical flow meters obsolete.

APPLICATIONS AND FEATURES

Cadillac® CMAG Pumped Condensate Meter Applications

The Cadillac® CMAG condensate flow meter is a totalizing device that is capable of measuring liquids of all types and consistency while providing an obstruction free flow path. This meter can be applied effectively for the following purposes:

- Gravity or Pumped Condensate applications where precise flow measurements are required.

- Hot or Chilled water energy measurements where high accuracy is required or where there is limited piping straight run or flow profiling exists.

- Domestic Hot water where modulating flows require very high turndown capabilities, while maintaining high accuracies.

- Domestic drinking or potable water applications where modulating flows require very high trun-down capabilities, while maintaining high accuracies.

- Any fluid with a conductivity above 3 uS/cm2, process temperatures below 350ºF and pressures at or below ANSI 300 Lb rating

Cadillac® CMAG Pumped Condensate Meter Features

The Cadillac® CMAG pumped condensate flow meter is the number one choice due to accuracy, rangeability, longevity, modern electronics, and independent flow profile.

Accuracy

+/-0.25% of the reading for liquids with 1.5 pipe diameters of piping straight run up and downstream from the meter’s centerline.

+/- 0.50% of reading for liquids without any piping straight run at all

Rangeability

Typically 300 to 1 turndown or better at +/- 0.25% accuracy, 400 to 1 turndown at +/ 0.50% accuracy, 500 to 1 turndown at +/- 1.00% accuracy With seasonal heating/cooling load variation, the need for a large turndown is essential. Cadillac® magnetic flow meters will accurately measure all load requirements with proper sizing.

Longevity

Mean time between failure (MTBF) of 40 years. With no moving parts and through simple robust design the meter has unmeasured life expectancy.

Modern Electronics

All Meters are equipped with electronics capable of registering locally, remotely or interfacing with an energy management system. With Modbus and Profibus communications now available the electronics now provide a true digital output to any energy management system.

Flow Profile Independent

The flow meter does not require traditional flow conditioning or piping straight run. Piping straight run from the centerline of the meter is 1.5 pipe diameters, which is essentially the mating flange face of the piping system in CMAG meters under 6” in size.

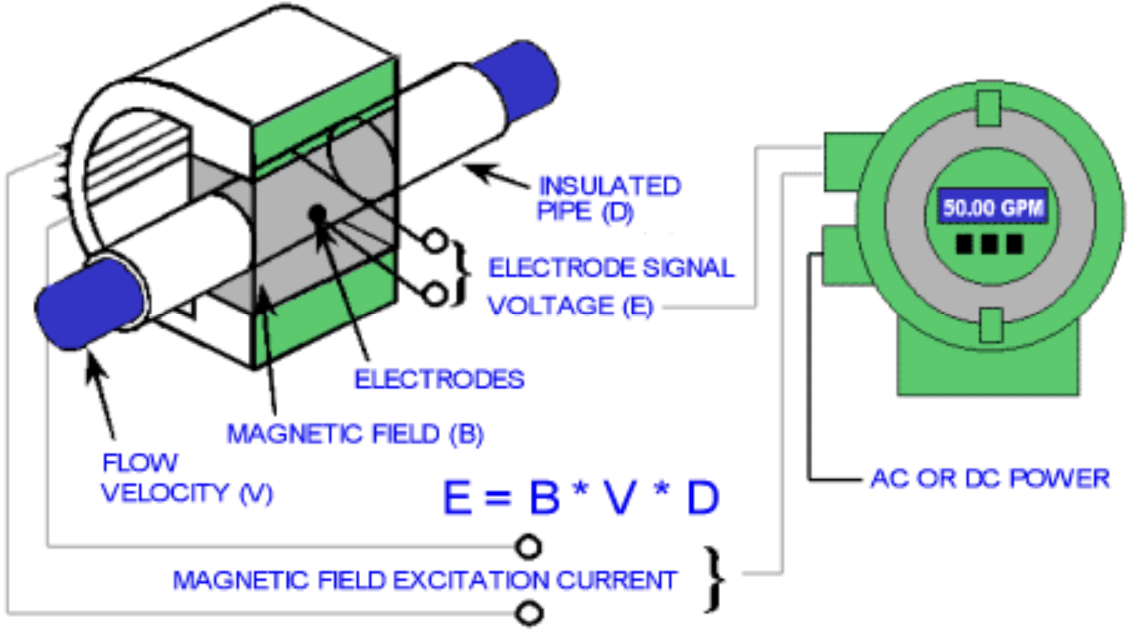

OPERATION PRINCIPLES

Cadillac® CMAG Pumped Condensate Meter – Principles of Operation

To understand the operation principles for Cadillac® CMAG Condensate Meter, it’s important to define Faraday’s law. It states that when you move a conductor perpendicular through a magnetic field, a voltage will be induced proportional to the velocity of the conductor. A magnetic field is created by a set of coils which are encapsulated and rigidly retained in the meter flow tube and, when a conductive liquid moves through that magnetic field, a pair of electrodes measures the voltage induced by the movement of the liquid. The measurement is independent of conductivity changes in the liquid as long as it remains above the minimum threshold of 3 uS/cm2.

The relationship between the liquid velocity and the induced voltage is expressed in a meter K-factor. The meter K-factor is unique to each and every meter and is documented during a NIST traceable flow test completed prior to shipment. With the K-factor established a highly accurate volumetric flow is calculated by multiplying the cross sectional area of the flow tube by the measured liquid velocity. This volumetric relationship can then be converted to various engineering units and the flow meter converter can then retransmit this information with a 4-20 mA current signal and/or conditioned pulse. An optional integral LCD Indicator/Totalizer is available to locally display and totalize in whatever engineering units preferred.

DIMENSIONS AND SPECS

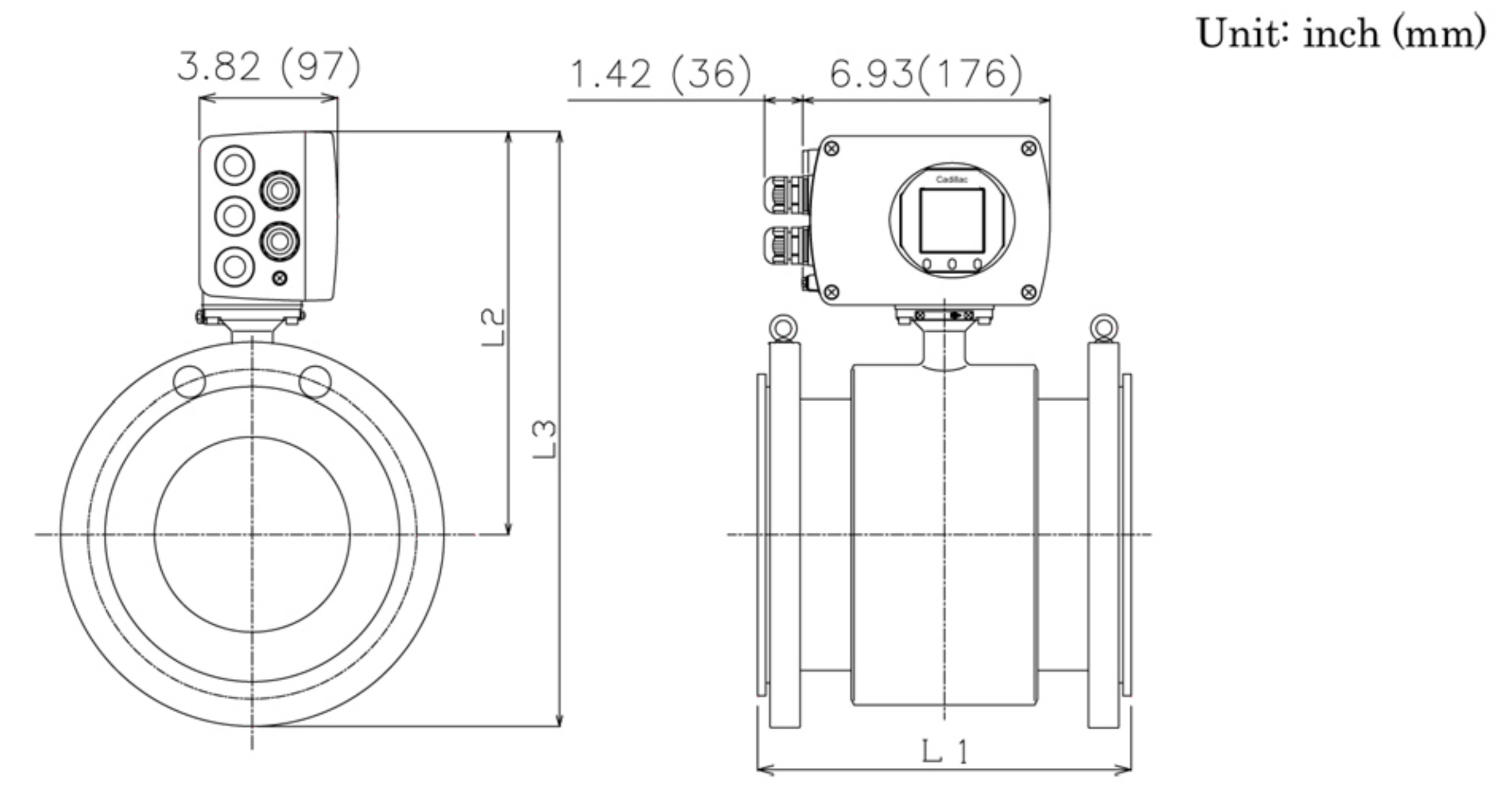

Cadillac® CMAG Magnetic Meter – Dimensions

The Cadillac® CMAG magnetic meter’s dimensions are outlined below. Please reference the letters with the chart for each meter size.

| Meter Size | 0.5″ | 1.0″ | 1.5″ | 2.0″ | 3.0″ | 4.0″ |

| “L1” (face to face) | 5.51″ | 6.30″ | 6.69″ | 7.09″ | 9.06″ | 9.45″ |

| “L3” (top to bottom) | 9.88″ | 10.71″ | 11.34″ | 12.20″ | 13.66″ | 14.45″ |

| “L2” (centerline to top) | 7.99″ | 8.23″ | 8.58″ | 9.13″ | 10.04″ | 10.31″ |

| Weight ANSI Class 150 lb |

14 lbs | 18 lbs | 23 lbs | 29 lbs | 45 lbs | 58 lbs |

| Meter Size | 6.0″ | 8.0″ | 10.0″ | 12.0″ | 14.0″ | 16.0″ | 18.0″ |

| L1 | 10.24″ | 11.81″ | 13.78″ | 15.75″ | 17.72″ | 19.69″ | 21.65″ |

| L3 | 16.73″ | 18.70″ | 21.06″ | 23.15″ | 24.37″ | 26.65″ | 28.74″ |

| L2 | 11.22″ | 12.20″ | 13.18″ | 14.37″ | 14.72″ | 15.63″ | 16.54″ |

| Weight ANSI Class 150 lb |

86 lbs | 128 lbs | 265 lbs | 315 lbs | 375 lbs | 475 lbs | 650 lbs |

Cadillac® CMAG Magnetic Flow Meter – General Specifications

Cadillac® CMAG Magnetic Flow Meter includes the following specifications:

- Meter will consist of a full-bore body with encapsulated and rigidly retained set of coils.

- Meter available with remote or integral electronics with indication and totalization.

- Meter operates at +/- 0.25% accuracy without flow profiling or piping straight run exceeding 1.5 pipe diameters from meter centerline.

- Meter available with pulse and analog (4-20 mA) outputs.

- Meter will provide instantaneous and totalized flow available at local indicator or remotely through outputs.

- Meter measures flow using Faraday’s law (Induce voltage is directly proportional to the velocity of the conductive liquid)

- Meter K-factor is stable and not influenced by external piping or mounting orientation.

- Meter will have uniform magnetic field flux distribution eliminating piping straight run and flow profiling.

- Meter will measure fluids with conductivity greater than or equal to 3.0 uS/cm2

- Meter fluid temperature range:

-

- (14°F to 176°F) with integral or remote electronics and EPDM liner.

- (14°F to 248°F) with integral or remote electronics and PFA liner.

- (14°F to 248°F) with integral electronics and Ceramic liner.

- (14°F to 356°F) with remote electronics and Ceramic liner.

- Meter flow tube operating pressure rating: ANSI 150 or ANSI 300

- Meter power supply: 100-240 VAC, 50/60 Hz (Optional 24Vdc). Power consumption approximately 14 watts

- Meter will have empty pipe detection and contact (DO) available for alarming.

INSTALLATION

Cadillac® CMAG Pumped Condensate Meter – Installation

Traditional Installation requirements have been redefined with the Cadillac® CMAG magnetic condensate flow meter. Employing coil and plate shaping techniques the Cadillac® meter provides a uniform magnetic field within the entire flow tube, allowing the meter to measure and sample voltage uniformly from the entire flow tube area. In addition, the electronics provide high frequency DC square wave signal generation and flow signal sampling, enabling fast response to turbulent or tumbling flow conditions that may occur without a fully developed flow profile.

In practice, this means the Cadillac® magnetic flow meters do not require traditional piping straight run or flow conditioning, and may be installed next to elbows, tees, valves, etc. without any effect in meter accuracy or stability.

In comparison, the straight pipe run requirements for all other magnetic flow meters are as follows:

Downstream of the meter:

- Expander (2-5) diameters

- Tee – (2-5) diameters

- Elbow – (2-5) diameters

- Valves – (2-10) diameters

Upstream of the meter:

- Expander – (10) diameters

- Tees – (5) diameters

- Elbow (5) diameters

- Valves – (10) diameters

Unlike other technologies such as turbine, variable orifice, pitot tube, orifice plates/DP cells, and Vortex, including the Cadillac® Vortex flow meter, magnetic flow meters do not have a low flow cutoff, essentially allowing the meter to read to zero while still provide an accurate measurement. With such a wide flow range capability for the technology, most applications can be addressed with meters at full line size.

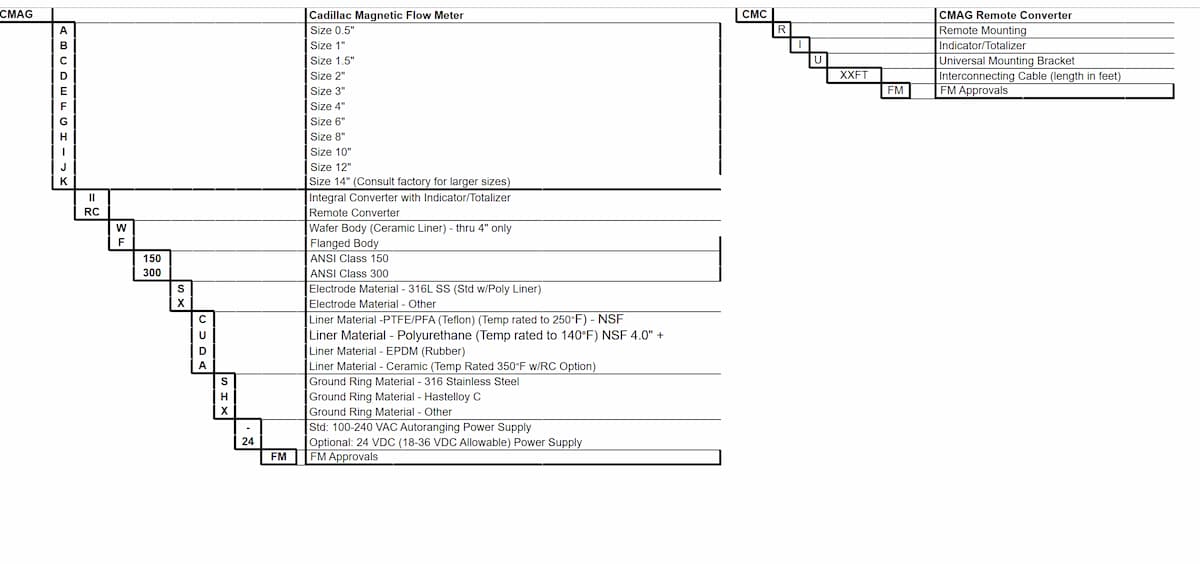

MODEL CODE

CMAG Model Code

FAQ for the CMAG Pumped and Gravity Condensate Meter

Q1: What is the CMAG Pumped & Gravity Condensate Meter used for?

The CMAG is designed to accurately totalize flow for both pumped and gravity condensate systems. It measures conductive liquids—like condensate and hot/chilled water—using a non-invasive, obstruction-free magnetic flow tube.

Q2: How accurate is the CMAG under different piping conditions?

With at least 1.5 diameters of straight pipe run upstream and downstream, the CMAG delivers ± 0.25% accuracy. For sizes 2″ and under, or when straight-run isn’t available, it still performs at ± 0.50% without requiring a flow conditioner.

Q3: What is the turndown ratio for the CMAG?

Standard turndown is 300:1 at ± 0.25% accuracy, extending to 400:1 at ± 0.50%, and up to 500:1 at ± 1.00%. This makes it ideal for applications with variable flow, such as seasonal HVAC loads or low-flow returns.

Q4: Does the CMAG require regular maintenance or calibration?

No. The CMAG has zero moving parts, no wear components, and requires no periodic calibration. With a typical service life exceeding 40 years, it’s engineered for long-term reliability with virtually no maintenance.

Q5: What types of fluids can it measure?

It measures any conductive fluid with a minimum conductivity of 3 µS/cm². This includes condensate, chilled water, and other conductive process fluids.

Q6: How does the CMAG measure flow?

The CMAG operates on Faraday’s Law. As conductive fluid moves through its magnetic field, voltage is generated and picked up by electrodes. That signal is then converted into a volumetric flow reading using a pre-set calibration factor.

Q7: What outputs and integrations are supported?

The CMAG supports analog (4–20 mA) and pulse outputs. Modbus and Profibus communication protocols are also available. It can be paired with a local LCD Indicator/Totalizer to display real-time readings and totals.

Q8: What are the installation requirements?

The CMAG only needs 1.5 diameters of straight pipe upstream and downstream—no additional flow conditioning required. For gravity-fed systems, a “wet leg” should be installed to keep the meter fully flooded.

Q9: Is the CMAG suited for retrofit or space-constrained installations?

Yes. Its compact design, minimal straight-run requirements, and profile-independent measurement make it a strong choice for retrofit projects and tight mechanical spaces.

Q10: How does the CMAG compare to mechanical condensate meters?

Unlike traditional meters with moving parts, the CMAG is not susceptible to wear, clogging, or drift. It provides better low-flow sensitivity, a broader turndown ratio, and consistent accuracy—making it a clear upgrade from legacy technologies.

Related Articles

Ultrasonic Flow Meters: Non-Invasive Measurement for Modern Systems

In today’s energy-conscious world, precise measurement is no longer optional—it’s a necessity. Whether you’re managing a commercial building, optimizing an HVAC system, or streamlining industrial processes, having accurate flow data is crucial. That’s where ultrasonic...

The BTU Energy Meter Installation Guide

In the fast-moving world of energy management, precision is everything. That’s why more businesses, facility managers, and HVAC professionals are turning to BTU energy meters for reliable and accurate measurement of thermal energy consumption. This BTU energy meter...

GET A FREE QUOTE FOR YOUR NEEDS